INNOVA planetary ball mill includes a vertical type, a horizontal type, and so on. With full function, high efficiency, and low noise, it is an ideal equipment for scientific research institutions, universities, and enterprise laboratories to obtain research samples.

FEATURES

IPB-A Series Semi-circle Model Vertical Planetary Ball Mill

Fashion Design:3D curve shape design, elegance, and fashion

Exquisite workmanship: Delicate and Precise

Special Drive Gear: Special gear with low noise, lower about 15-20db compared with common gear.

Convenient Operation: Humanization design, Convenient operation.

Visual Window

Planetary Mechanism: Planetary disc by whole casting, New pressure pole, delicate and good appearance, Stable rotation speed, High efficiency, ultrafine grinding.

Frequency Converter Control: Expected rotation speed can be selected according to experiment need, the minimum scale of rotation speed is 0.2 rpm. The frequency converter owns a protection device of under-voltage and over-voltage which provides the necessary protection for the motor.

IPB-2-12 Series Square Model Vertical Planetary Ball Mill

Planetary Mechanism: Planetary disc by whole casting, Newpressure pole, delicate and good appearance, Stable rotate speed, High efficiency, ultrafine grinding

Pneumatic Rod:Support force is constant in process of running with appropriate damping, safe and convenient to operate.

Frequency Converter Control: Expected rotation speed can be selected according to experiment need, minimum scale of rotate speed is 0.2 rpm. Frequency converter owns protection device of under voltage and over voltage which provides necessary protection for motor.

Hole of Cooling Fan: Running of the machine at a high speed enhances speed of air flow inside the machine effectively and improving of cooling speed ensures the stable operation for long time.

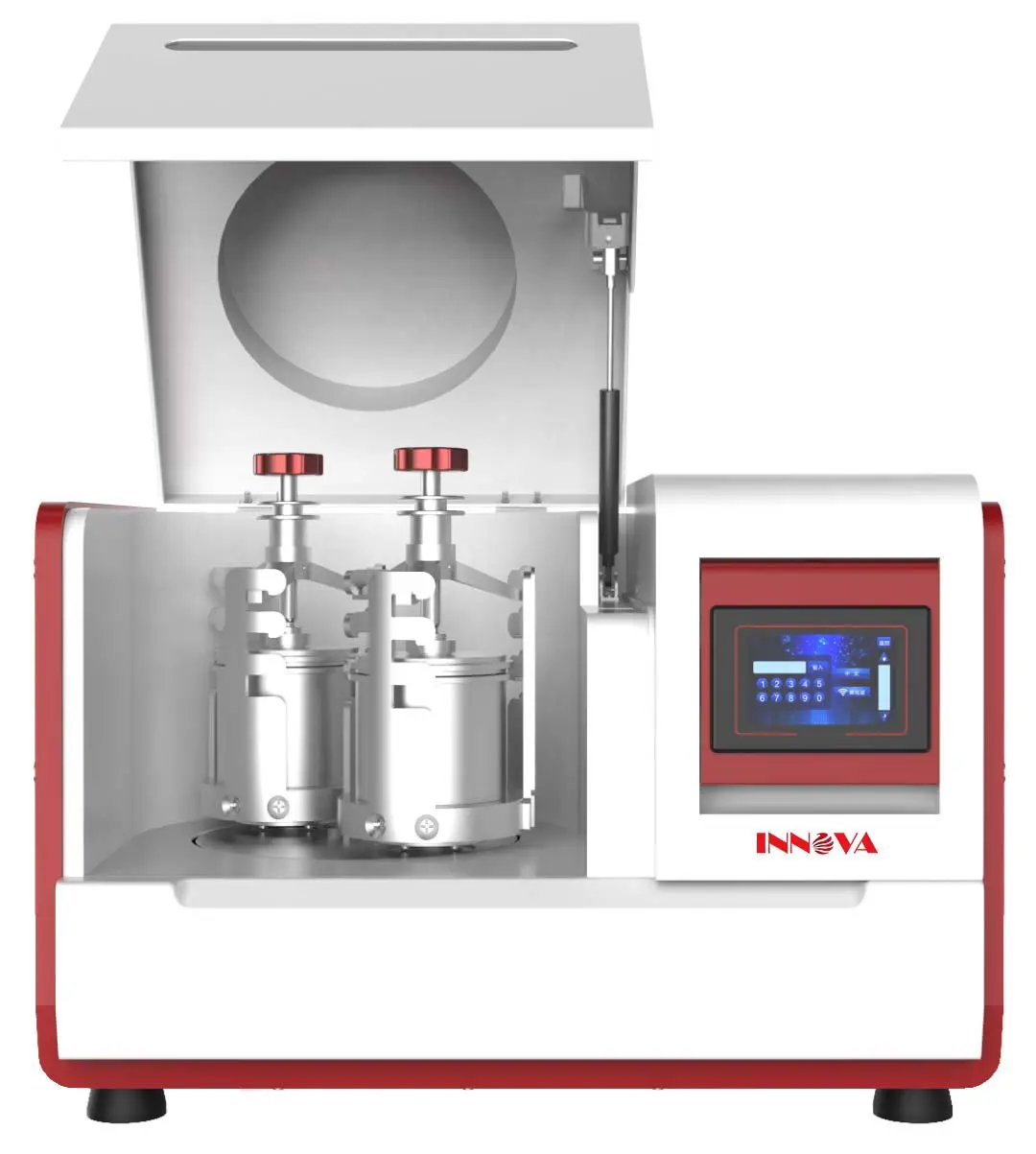

IPB420 Series Square Model Vertical Planetary Ball Mill

It can be run continuously for a long time.

Extremely high speed can grind the sample to sub micron or even nanometer fineness.

Both forward and backward can run , can set interval time and pause time , prevent sample aggregation and better heat dissipation.

It can set two different speed of grinding time, aiming at the special requirements of different samples.

Grinding jars volume 50-500ml , 6 different materials , broaden application range of products.

Automatic ventilation in grinding chamber.

10 sets of grinding parameters can be stored.

LCD touch screen, no need to press button.

The instrument is convenient to operate, accords with the principle of artificial science, with casters, and convenient to move.

The instrument is equipped with a safety lock device to ensure the experimental safety of the operator.

IPB-(20-100) series Production Model Large Planetary Ball Mill

Large planetary ball mill for production is a kind of large-sized machine designed, enlarged and manufactured on basis of principle of small ball mill, which mainly applies batch production.

Shell of the machine is made of thick steel by welding process with advantages of high strength, Impact resistance, anti deformation,delicate workmanship, solid appearance.

Machined parts are made by heat treatment process and NC machining process.

Gear box is seal with groove embedded structure, drive gear is wear resistant and precise, frame and structural parts are designed with full consideration of resonance so as to ensure stability, safety and reliable operation under high load of machine that realizes to reduce noise.

Design of self lubricating device and liquid oil reduces noise greatly and oil level gauge benefits replacement.

Hoisting and pouring device are integrated designed and pouring device is adopted with vibration screening and discharging technology.

Easy and quick for operators to unload pots, discharge powder and load pots with reduction of labor intensity and improvement of production efficiency.

IHPB-(0.4-4)L series Light Horizontal Planetary Ball Mill

There is not regular flat bottom for pots when the machine makes planetary movement.In process of grinding, grinding balls are influenced by self gravity while balls are being influenced by two centrifugal forces of revolution and rotation, which benefit to strengthen degree of disordered movement of balls and materials. It greatly improves effects and efficiency of grinding. Because the pot has not flat bottom when rotating, the materials won’t be sunk to the bottom of pot.

With four grinding pots installed horizontally and symmetrically on the vertical planetary plate.

Simple structure and convenient to be operated. The machine often applies small batch sample of experimental research.

Shell of the machine is designed to be in new and fashion style that is stamped and formed by precise molding with delicate, generous and stable outlook.

Planetary disc is made by whole casting and machined parts are made by NC machining process, drive gears are made precisely from special materials. All these factors ensure stability and low noise of machine when running at high speed.

Pressing devise of pots is convenient to operate, safe and reliable.

IHPB-(6-80)L Series Large Horizontal Planetary Ball Mill

Large horizontal planetary ball mill is mainly used for medium or small batch production of grinding.

With the bracket structure supported by both ends of double plates. Stability and anti load capacity of the machine are improved much efficiently, it solves limit of light load of light horizontal mill.

Shell of the machine is made of thick steel by welding process with high strength, Impact resistance, anti deformation,delicate workmanship, solid appearance.

Machined parts are made by heat treatment process and NC machining process, drive gear is made of special materials precisely which ensure stability, safety and low noise of the machine when running at high speed.

Designed function of brake lock ensures safe and reliable operation of hanging pot, loading pot and locking pot.

Hoisting and pouring device are integrated designed and pouring device is adopted with vibration screening and discharging technology.

Easy and quick for operators to unload pots, discharge powder and load pots with reduction of labor intensity and improvement of production efficiency.

IFPB series 360°Full-directional Planetary Ball Mill

Full-directional planetary ball mill is developed on basis of vertical planetary ball mill with an increase of turning function of planetary disc. The planetary disc and pots are turning at 360° tipping bucket type in a tridimensional space while they are making planetary movement. Multidirectional and multidimensional movement increase degree of disorder movement of balls and materials. All materials in the ball are grinded without any dead space and grinded powder is much more uniform and fine. This model solves problems of sink bottom and clay pot completely.

IDPB series Dual Planetary Ball Mill

Dual planetary ball mill is a kind of typical and high energy ball mill, which is adopted with dual planetary structure where big plate brings small plate to make movement. Radius of revolution and rotation speed is much larger than that of common ball mill in same size. Centrifugal force is increased double times, collision, shear and friction force between the balls increases significantly. Thus effects and efficiency of grinding is improved greatly. Partial materials can be grinded to nano scale.

IPB-L series Cryogenic Planetary Ball Mill

Cryogenic planetary ball mill is composed of planetary ball mill and refrigeration device. Most of materials are heating-up because of friction and exothermal reaction in process of grinding at high speed, which may cause changes of chemical and physical properties of materials and lead to negative effect of grinding. Cryogenic planetary ball mill is mainly used for grinding materials which need to control their temperature.

Microcomputer Planetary Ball Mill

Microcomputer planetary ball mill is a kind of equipment configured with a touch screen of operation & control system based on common planetary ball mill, which improves its grade and operation performance. Microcomputer planetary ball mill is mainly to meet high level clients’ requirements of higher quality and better operation performance. Hardware of control system is adopted with famous brand’s products with strong functions of password setting, programming freely, storage and call of multiple sets of programs, process monitor and fault alarm. Visual operation and simple humanization realize friendly human-computer interface.

Ultrasonic Planetary Ball Mill

Ultrasonic planetary ball mill is based on 1/2L Vertical planetary ball mill. The equipment is mainly used for mixing and fine grinding with high particle size requirements. When using traditional ball mill equipment, sinking, agglomeration, wall sticking, and agglomeration will occur. materials of other phenomena. Our ultrasonic planetary ball mill is small in size, complete in function, high in efficiency and

low in noise. It is an ideal equipment for scientific research institutes, universities, and enterprise laboratories to obtain research samples. It is equipped with a vacuum ball mill tank and can grind samples in a vacuum state.

Planetary Ball Mill

SPECIFICATIONS

| Model | IPB-0.4A | IPB-2A | IPB-4A | IPB-8A | IPB-10A | IPB-12A | IPB-16A | |

|---|---|---|---|---|---|---|---|---|

| Specification | 0.4L | 2L | 4L | 8L | 10L | 12L | 16L | |

| Volume of each matched pot | 50-100mL | 50-100mL | 250-1000mL | 1-2L | 1-2.5L | 1-3L | 2-4L | |

| Quantity | 4pcs | |||||||

| Feed Size | Soil ≤10mm, Other materials ≤3mm | |||||||

| Final Fineness | Minimum Granularity can be reached to 0.1μm | |||||||

| Motor power (KW) | 0.25 | 0.75 | 1.5 | 3 | ||||

| Total run time of setting (min) | 1-9999 | |||||||

| Reciprocal running time (min) | 1-999 | |||||||

| Adjustable speed | Revolution (rpm) | 45-435 | 35-335 | 35-290 | 30-255 | |||

| Rotation (rpm) | 90-870 | 70-670 | 70-580 | 60-510 | ||||

| Noise≤db | 58±5 | 60±5 | 65±5 | |||||

| Speed control mode | Frequency Control | |||||||

| Net weight (kg) | 29 | 80 | 132 | 203 | ||||

| Dimension (mm) | 500×300×340 | 750×470×564 | 880×560×670 | 950×600×710 | ||||

| Model | IHPB-0.4A | IHPB-1A | IHPB-2A | IHPB-4A | |

|---|---|---|---|---|---|

| Specification | 0.4L | 1L | 2L | 4L | |

| Volume of each matched pot | 50-100mL | 50-200mL | 50-500ml | 250-1000ml | |

| Quantity | 4pcs | ||||

| Feed Size | Soil ≤10mm, Other materials ≤3mm | ||||

| Final Fineness | Minimum Granularity can be reached to 0.1μm | ||||

| Power supply | 220V-50HZ | ||||

| Motor power (KW) | 0.75 | ||||

| Total run time of setting (min) | 1-9999 | ||||

| Reciprocal running time (min) | 1-999 | ||||

| Adjustable speed | Revolution (rpm) | 35-335 | |||

| Rotation (rpm) | 70-670 | ||||

| Noise≤db | 58±5 | 60±5 | |||

| Speed control mode | Frequency Control | ||||

| Net weight (kg) | 86 | ||||

| Dimension (mm) | 700×510×570 | ||||

| Model | IPB-2 | IPB-4 | IPB-6 | IPB-8 | IPB-10 | IPB-12 | IPB-20 | IPB-40 | IPB-60 | IPB-100 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification | 2L | 4L | 6L | 8L | 10L | 12L | 20L | 40L | 60L | 100L | ||

| Volume of each matched pot | 50-500mL | 250-1000mL | 1-1.5L | 1-2L | 1-2.5L | 1-3L | 2-5L | 5-10L | 10-15L | 20-25L | ||

| Quantity | 4pcs | |||||||||||

| Feed Size | Soil ≤10mm, Other materials ≤3mm | |||||||||||

| Final Fineness | Minimum Granularity can be reached to 0.1μm | |||||||||||

| Power supply | 220V-50HZ | 380V-50HZ | ||||||||||

| Motor power (KW) | 0.75 | 1.5 | 4 | 5.5 | 7.5 | 11 | ||||||

| Total run time of setting (min) | 1-9999 | |||||||||||

| Reciprocal running time (min) | 1-999 | |||||||||||

| Adjustable speed | Revolution (rpm) | 35-335 | 35-290 | 25-215 | 20-195 | 27-174 | 27-160 | |||||

| Rotation (rpm) | 70-670 | 70-580 | 50-430 | 40-390 | 40-260 | 40-240 | ||||||

| Noise≤db | 60±5 | 65±5 | 68±5 | |||||||||

| Speed control mode | Frequency Control | |||||||||||

| Net weight (kg) | 93 | 150 | 330 | 468 | 900 | 1250 | ||||||

| Dimension (mm) | 750×470×564 | 900×600×640 | 1200×750×920 | 1400×850×1160 | 1600×990×1250 | 1750×1140×1330 | ||||||

| Model | IDPB-0.4 | IDPB-1 | IDPB-2 | IDPB-4 | IDPB-6 | |

|---|---|---|---|---|---|---|

| Specification | 0.4L | 1L | 2L | 4L | 6L | |

| Volume of each matched pot | 50-100mL | 250mL | 500mL | 1000mL | 1500mL | |

| Quantity | 4pcs | |||||

| Feed Size | Soil ≤10mm, Other materials ≤3mm | |||||

| Final Fineness | Minimum Granularity can be reached to 0.1μm | |||||

| Power supply | 220V-50HZ | 380V-50HZ | ||||

| Motor power (KW) | 0.75 | |||||

| Total run time of setting (min) | 1-9999 | |||||

| Reciprocal running time (min) | 1-999 | |||||

| Adjustable speed | Revolution (rpm) | 70-560 | ||||

| Rotation (rpm) | 140-1120 | |||||

| Noise≤db | 58±5 | 60±5 | ||||

| Speed control mode | Frequency Control | |||||

| Net weight (kg) | 250 | |||||

| Dimension (mm) | 1150×800×760 | |||||

| Model | IPB420 | ||

|---|---|---|---|

| Feed Size | <15mm | ||

| Final Fineness | About 0.1 µm(Colloidal)/ About 1 µm (General grinding) | ||

| Feeding Quantity | ≤2×220ml | ||

| Setting Grinding time | 1s-99h59min59s | ||

| Direction Setting | Direction reversa,Interval,Pause, Two stage grinding | ||

| Sun Wheel speed | 100rpm-650rpm | ||

| Sun Wheel diameter | 305mm | ||

| Speed Ratio | 1: -2 | ||

| Grinding Environment range | Dry,Wet | ||

| Grinding Platform | 2 | ||

| Grinding Jar volume | 50ml,80ml,125ml,250ml,500ml | ||

| Grinding Jar material | Chrome Steel,Stainless steel,Tungsten carbide,Agate, Corundum, Zirconia | ||

| Number of grinding jars placed | 2/4 | ||

| Stacking Jars volume | 50ml/80ml,placed 4 | ||

| Grinding Ball diameter | 0.1mm-1mm,2mm,3mm,5mm, 7mm,10mm,15mm,20mm,25mm,30mm | ||

| Parameter Storage | 10 groups | ||

| Combined Cycle number | 1-20 times | ||

| Dimension (mm) | 656mm×517mm×396mm | ||

| Net Weight | Approx. 100Kg | ||

| Electrical Parameters | 220V/750W | ||

| Model | IHPB-2~6B | IHPB-8B | IHPB-10B | IHPB-12B | IHPB-16B | IHPB-20B | IHPB-40B | IHPB-60B | IHPB-80B | IHPB-100B | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification | 2~6L | 8L | 10L | 12L | 16L | 20L | 40L | 60L | 80L | 80L | ||

| Volume of each matched pot | 0.05-1.5L | 1-2L | 1-2.5L | 1-3L | 2-4L | 2-5L | 5-10L | 10-15L | 15L-20L | 15-20L | ||

| Quantity | 4pcs | |||||||||||

| Feed Size | Soil ≤10mm, Other materials ≤3mm | |||||||||||

| Final Fineness | Minimum Granularity can be reached to 0.1μm | |||||||||||

| Power supply | 220V-50HZ | 380V-50HZ | ||||||||||

| Motor power (KW) | 1.5 | 3 | 4 | 5.5 | 7.5 | 11 | 11 | |||||

| Total run time of setting (min) | 1-9999 | |||||||||||

| Reciprocal running time (min) | 1-999 | |||||||||||

| Adjustable speed | Revolution (rpm) | 35-335 | 35-290 | 30-240 | 25-215 | 20-206 | 35-193 | 35-193 | ||||

| Rotation (rpm) | 70-670 | 70-580 | 60-480 | 50-430 | 50-310 | 50-290 | 50-290 | |||||

| Noise≤db | 60±5 | 65±5 | 68±5 | |||||||||

| Speed control mode | Frequency Control | |||||||||||

| Net weight (kg) | 256 | 370 | 440 | 700 | 760 | 1020 | 1160 | 1160 | ||||

| Dimension (mm) | 1220×620×810 | 1320×670×920 | 1530×750×960 | 1620×840×1040 | 1770×860×1100 | 1860×1050×1280 | 2100×1150×1370 | 2100×1150×1370 | ||||

| Model | IFPB-2 | IFPB-4 | IFPB-6 | IFPB-8 | IFPB-10 | IFPB-12 | IFPB-16 | IFPB-20 | IFPB-40 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Specification | 2L | 4L | 6L | 8L | 10L | 12L | 16L | 20L | 40L | |

| Volume of each matched pot | 50-500mL | 250-1000mL | 1-1.5L | 1-2L | 1-2.5L | 1-3L | 2-4L | 2-5L | 4-10L | |

| Quantity | 4pcs | |||||||||

| Feed Size | Soil ≤10mm, Other materials ≤3mm | |||||||||

| Final Fineness | Minimum Granularity can be reached to 0.1μm | |||||||||

| Power supply | 220V-50HZ | 380V-50HZ | ||||||||

| Motor power (KW) | 0.75 | 1.5 | 3 | 4 | 5.5 | |||||

| Total run time of setting (min) | 1-9999 | |||||||||

| Reciprocal running time (min) | 1-999 | |||||||||

| Adjustable speed | Revolution (rpm) | 35-335 | 35-290 30-290 35-290 | 30-255 | 25-215 | 20-195 | ||||

| Rotation (rpm) | 70-670 | 70-580 | 60-510 | 50-430 | 40-390 | |||||

| Noise≤db | 58±5 | 60±5 | 65±5 | 70±5 | ||||||

| Speed control mode | Frequency Control | |||||||||

| Net weight (kg) | 317 | 420 | 550 | 1150 | 1400 | |||||

| Dimension (mm) | 1330×770×850 | 1360×850×930 | 1530×940×1100 | 1700×1210×1300 | 1900×1450×1480 | |||||

Planetary Ball Mill

BROCHURE

Please wait while flipbook is loading. For more related info, FAQs and issues please refer to DearFlip WordPress Flipbook Plugin Help documentation.

GET A QUOTE

Please Fill Out the Form Below to Receive an Offer for FenixES Products and Services

by

by