Innova lifting glass reactor is suitable for pilot production in chemical, pharmaceutical, material synthesis, etc. It usually works with dynamic temperature control system to meet experimental requirements.

FEATURES

Lifting glass reactors are mainly used for synthetic reaction, distillation and concentration of different types of materials. The reactor can be lifted and rotated. The reactor can be pumped to a negative pressure state according to some experimental requirements.

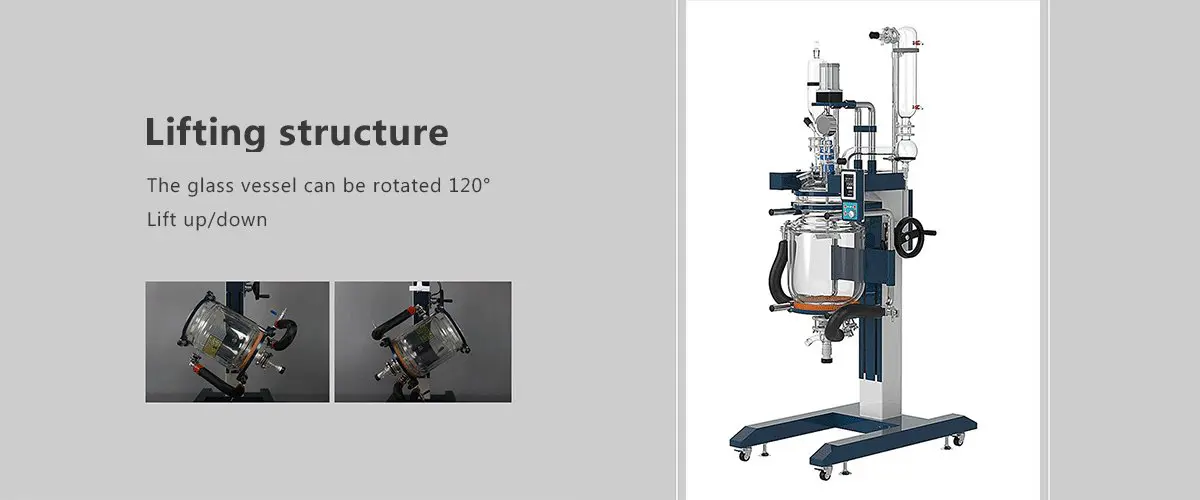

● The reaction vessel and the lid can be separated, the glass vessel can be lifted up, and can be angled 120 degree both sides, which makes it more convenient to operate and clean.

● 4.3″, 65K true color LCD screen operation box, the torque value, temperature, running time, setting speed and actual speed can be displayed simultaneously.

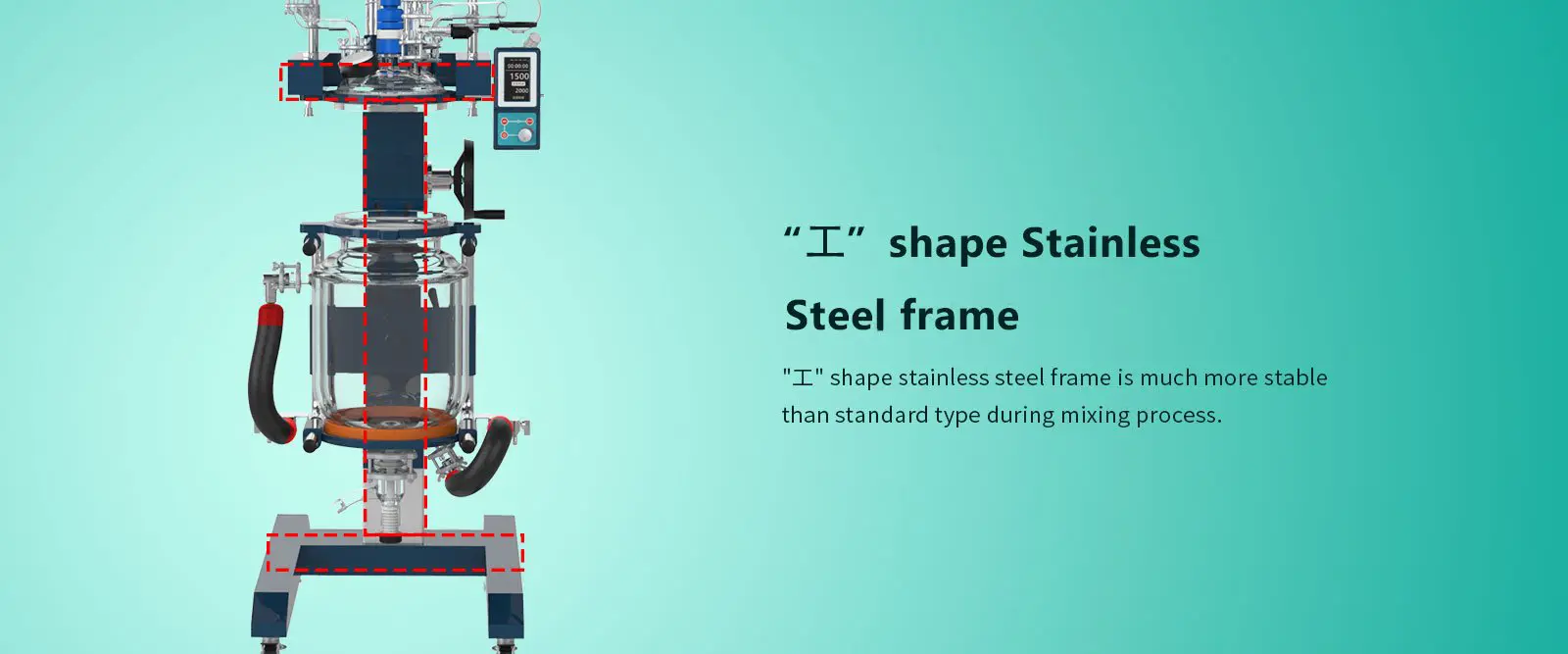

● “工” shape stainless steel frame is much more stable than standard type during mixing process.

● Wide working temperature range from -80℃ to 200℃.

● Openings are sealed with flanges, ensuring higher vacuum degree, easy to disassemble.

● Brushless DC motor for stable performance and long life time.

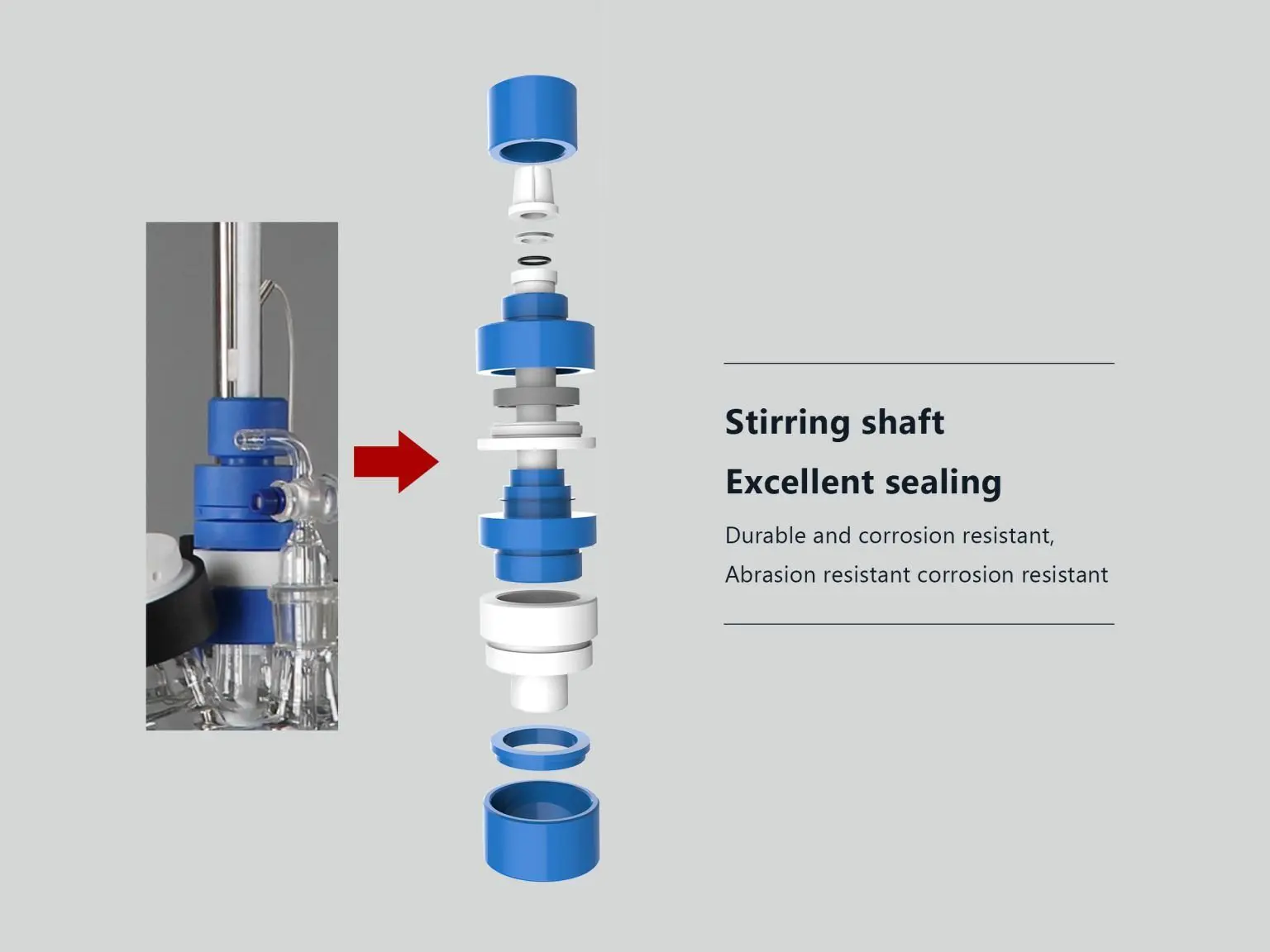

● Stirring shaft excellent sealing. Durable and corrosion resistant.

● Customized stirring paddle. Stainless steel coated with PTFE, corrosion resistant.

SPECIFICATIONS

Technical Data 1:

| Model | IGRL-10 | IGRL-10CE | IGRL-10Ex | IGRL-20 | IGRL-20CE | IGRL-20Ex | IGRL-50 | IGRL-50CE | IGRL-50Ex |

|---|---|---|---|---|---|---|---|---|---|

| Vessel volume | 10L | 20L | 50L | ||||||

| Jacket volume | 8L | 9L | 13L | ||||||

| Funnel volume | 1L | 1L | 1L | ||||||

| Glass material | High borosilicate glass 3.3 | ||||||||

| Operating pressure | Ordinary or negative pressure | ||||||||

| Working temperature | -80 ~ 200℃ | ||||||||

| Condenser cooling area | 0.245 m² | 0.420 m² | |||||||

| Stirring speed | 50~500rpm | 20~500rpm | 50~500rpm | 50~500rpm | 20~500rpm | 50~500rpm | 50~500rpm | 20~500rpm | 50~500rpm |

| Power supply | 220-240V 50/60Hz | 100-240V 50/60Hz | 220-240V, 50/60Hz | 220-240V, 50/60Hz | 100-240V, 50/60Hz | 220-240V, 50/60Hz | 220-240V, 50/60Hz | 100-240V, 50/60Hz | 220-240V, 50/60Hz |

| Dimensions(W×D×H) | 850×1100×2050mm | 860×1100×2500mm | |||||||

Technical Data 2:

| Model | IGRL-50F | ||

|---|---|---|---|

| Reactor lid openings | 50L | ||

| Jacket volume | 16L | ||

| Interface size of liquid outlet/inlet | Rc 3/4" | ||

| Condenser heat exchanging area | About 0.42 m² | ||

| Funnel volume | 2L | ||

| Material of glass parts | High borosilicate glass 3.3 | ||

| Reactor lid openings | Stirring port | 50# flange port | |

| Temperature sensor port | 35# flange port | ||

| Condenser connection port | 50# flange port | ||

| Vacuum gauge installation port | 35# flange port | ||

| Funnel elbow port | 35# flange port | ||

| Solid charging port | 80# flange port | ||

| Filter parts | Material | 1~250μm available | |

| Filtration accuracy | 1~250μm available | ||

| Performed filter plate hole size available | 30~50μm | ||

| 16~30μm | |||

| 7~16μm | |||

| 4~7μm | |||

| Filtration area | About 0.16m² | ||

| Material of filtration base plate | PTFE | ||

| Mobility | Lockable casters + adjustable foot | ||

| Working temperature range | -80~200℃ Pay attention to the Max. tolerable temperature of filter cloth | ||

| Max temperature difference inside/outside the vessel | △T≤80℃ | ||

| Operating pressure | Ordinary pressure | ||

| Max. jacket pressure | ≤0.03MPa | ||

| Max. filtration pressure difference | 0.1 MPa | ||

| Stirring motor power | 370W | ||

| Max. torque | 5.4N·m | ||

| Stirring speed range | 20~500rpm | ||

| Power supply | 100-240V, 50/60Hz | ||

| Material of sealing parts | PTFE | ||

| Lifting distance | About 350mm | ||

| Dimensions(W×D×H) | 1100×760×2050mm | ||

BROCHURE

Please wait while flipbook is loading. For more related info, FAQs and issues please refer to DearFlip WordPress Flipbook Plugin Help documentation.

GET A QUOTE

Please Fill Out the Form Below to Receive an Offer for FenixES Products and Services

by

by