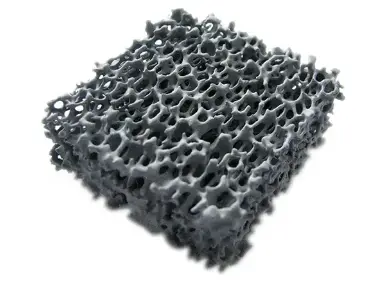

Foam metal, also known as metallic foam or metal foam, is a type of material that consists of a metal matrix with empty pores or cells throughout its structure.

Foam metal can be made from various metals, including aluminum, titanium, copper, nickel, and steel. The fabrication process involves adding a blowing agent or foaming agent to the molten metal, which creates gas bubbles that solidify within the material as it cools. This results in a foam-like structure with a high volume fraction of empty space.

FEATURES

The properties of foam metal can be customized by varying factors such as the metal type, cell size and shape, and overall density. Due to its porosity, foam metal exhibits excellent energy absorption and impact resistance, making it useful in applications such as lightweight structural components, thermal insulation, acoustic panels, and crash protection systems.

Foam metal also has unique thermal and electrical conductivity properties, as well as a large surface area, which makes it suitable for applications in heat exchangers, catalyst supports, batteries, and electrodes.

Overall, foam metal is a versatile material that combines the desirable characteristics of metals, such as strength and conductivity, with the benefits of a lightweight and porous structure

Properties of Metal Foam

The key properties of metal foam are as follows:

- Ultralight material (75–95% of the volume consists of void spaces)

- Very high porosity

- High compression strengths combined with good energy absorption characteristics

- Thermal conductivity is low

- High strength

Applications

The main applications of metal foams and porous metals are listed below:

- The closed variety is used for structural applications requiring load-bearing features, and for weight-saving and impact-absorbing structures in vehicles

- The open variety is ideal for vibration and sound absorption, filtration and catalysis at high temperatures, for heat exchange and in medical devices.

- The open variety is also useful in functional applications such as filtration and damping.

- Foam metal is being used as an experimental prosthetic in animals.

- Metal foams with high strengths can act as high-capacity impact-energy absorbers.

- Automotive industry – the foams reduce the number of parts in the car frame, facilitate assembly, thereby reducing costs and improving performance.

SPECIFICATIONS

| Material | Alumina | Silicon Carbide | Zirconia | Magnesia |

|---|---|---|---|---|

| Color | White | Grey Black | Yellow | Dark Yellow |

| Pore Density | 8-60ppi | 8-60ppi | 8-60ppi | 8-60ppi |

| Porosity | 80-90% | 80-90% | 80-90% | 80-90% |

| Refractoriness | ≤1100°C | ≤1500°C | ≤1700°C | ≤1000°C |

| Bending Strength | >0.6Mpa | >0.8Mpa | >1.0Mpa | >0.6Mpa |

| Compression Stength | >0.8Mpa | >0.9Mpa | >1.2Mpa | >0.8Mpa |

| Volume-Weight | 0.3-0.45g/cm³ | 0.35-0.5g/cm³ | 0.9-0.5g/cm³ | 0.35-0.5g/cm³ |

| Thermal Shock Resistance | 6 times 1000°C | 6 times 1000°C | 6 times 1000°C | 6 times 1000°C |

| Application | Aluminium, Aluminium alloys and other Non-ferrous alloys | Ductile Cast İron Malleable Cast İron Gray İron and other Cast İron | High melting point metal alloys like Steel, Alloy Steel Stainless Steel etc. | Magnesium and Heigh Active Alloy |

GET A QUOTE

Please Fill Out the Form Below to Receive an Offer for FenixES Products and Services

by

by